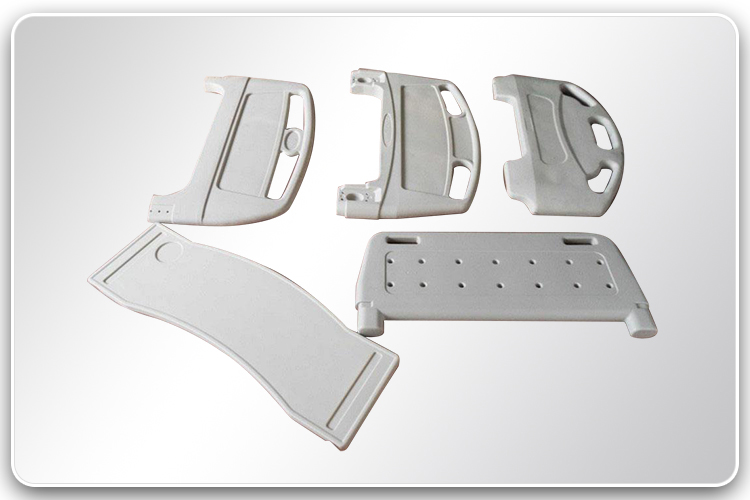

Description

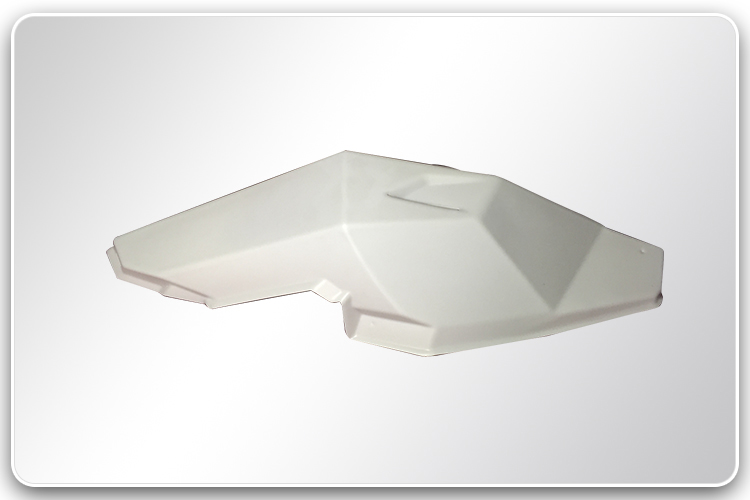

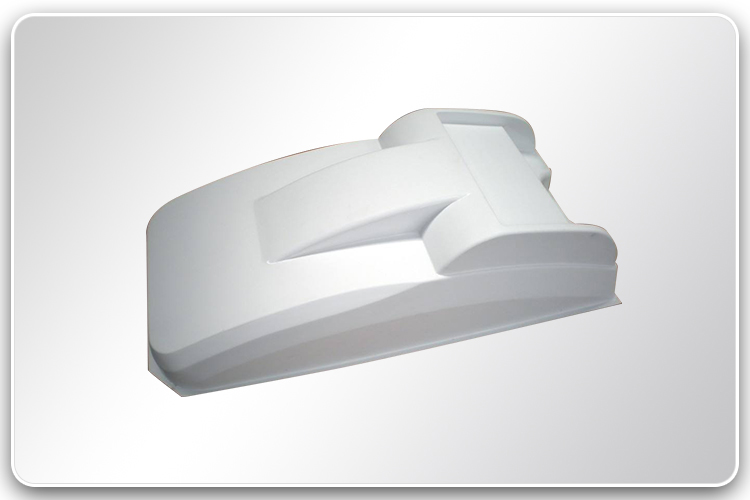

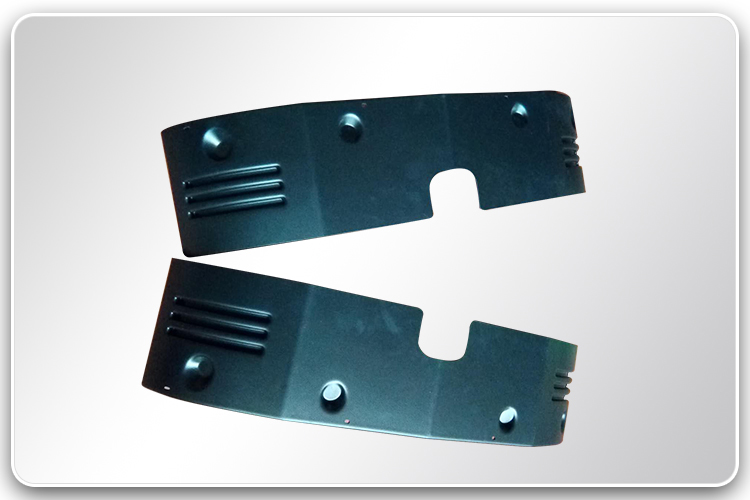

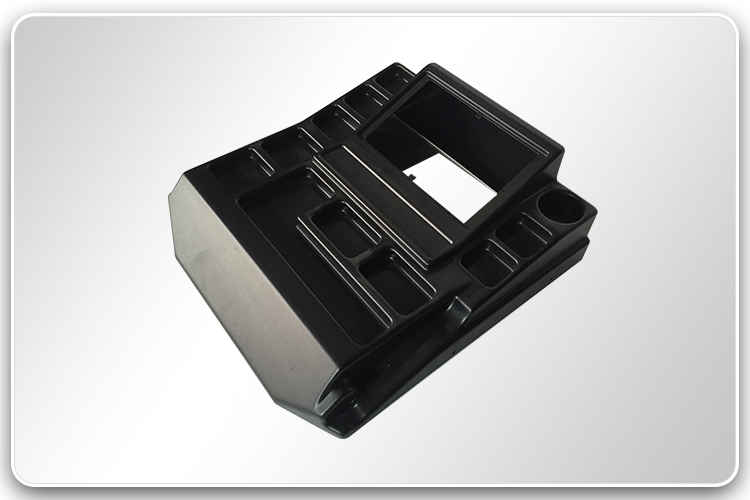

Thermoforming is a manufacturing process whereby a plastic sheet is heated to a pliable forming temperature, formed to a

specific shape in a mold, and trimmed to create a usable product. Auwell has

rich experience in manufacturing and supplying plastic thermoforming parts to

our worldwide clients.

There are two main types of forming process for plastic thermoforming

parts production: vacuum forming and pressure forming. Vacuum forming uses heat

and pressure to draw plastic sheets into its final configuration. Once a sheet

is heated and placed over a mold, a vacuum is used to manipulate it into its

desired shape. Pressure forming has many similarities to vacuum forming, but

has the added benefit of additional pressure. This pressure allows for greater

detail and texture, making it a solid choice when aesthetics is an issue. The

most common way from Auwell plastic thermoforming parts production is vacuum

forming.

Many uses are available for plastic thermoforming parts. One of the more

common is packaging, particularly rigid packaging for food and consumer goods,

but it has many other applications including automotive, machinery, medical

instruments, white goods, furniture, fitness equipment etc.

Plastic thermoforming parts production is a relatively low-cost process

compare to plastic injection, especially the tooling cost, in some cases, can

be 95% cheaper compare to plastic injection molds. Also, with much faster

development circle. The most common

material for plastic thermoforming parts production is ABS. The color can be

pre-ordered if the order quantity meets the MOQ requirements (normally

1,000kg). Also, paintable plastic is also available, allowing for a wide range

of customization to meet customer needs.

Техникалық сипаттамалары

-Material

ABS,ASA,PC,PEGT,HDPE,PSïPPVC,PMMA

-Материалдың қалыңдығы

0,2 мм-ден 8,0 мм-ге дейін

Advantages

-Rich Experience

More than 20 years of

experience in Plastic thermoforming parts development and part production, especially

to the European and North American markets, with solid understanding of the

material, technical and quality standards worldwide.

-Жылдам айналым

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell is able to deliver first sample in 2 weeks.

-Comprehensive Solution Provider

Auwell provides

comprehensive services for Plastic thermoforming parts development starting

from designing, through prototyping, tooling/fixture development, sampling,

mass production, and to logistic and post-sale support.

-QC қатаң саясаты

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection for Plastic thermoforming parts orders. Material

certificates include the mill certificate, 3rd party chemical components, and

mechanical property reports, as well as RoHS and REACH reports upon request. We

structure our processes, creating Flow Charts and Control Plans before

production, making sure all QC processes are in accordance with ISO9001-2015

requirements and drawing specifications.

-Flexible Payment Term

Құрал-саймандар үшін жалпы төлем мерзімі 50% -50% құрайды, бұл 50% депозит, алғашқы сынамадан кейін 50%. Формас өндірісі, біз икемді төлем шарттарын ұсынамыз, ақылға қонымды несие шарттары беріледі, клиент алған өніміне риза болған кезде ғана төлейді. Ұзақ мерзімді жобалар үшін біз жылдам жеткізілім талаптары бойынша инвентаризациялық қызметтерді ұсынамыз.

қосымша тауарлар

Plastic Injection Mold for Automotive Parts

Plastic Injection Mold for Automotive Parts

Plastic Injection Parts

Plastic Injection Parts

Пластикалық инъекцияны қалыпқа келтіру

Пластикалық инъекцияны қалыпқа келтіру

Резеңке және силиконды қалыптау

Резеңке және силиконды қалыптау

Пластикалық инжекциялық бөліктердің келесі каталогтары

Ауэлл шығарған және біздің бүкіл әлемге әйгілі адамдарға ұсынған

клиенттер. Мәліметтер алу үшін тиісті суреттерді басыңыз. Пожалуйста, өтінемін,

өнімнің көп бөлігі тек демонстрацияға арналған.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик